In this post we are going to share with you some interesting information about LPG bobtail delivery truck equipment.

But what is a bobtail for?

LPG (propane) has many uses for everyday life but is most commonly used to heat residential homes and businesses as well as fuelling private vehicles and fleets.

LPG is transported under pressure by transport trucks and local delivery trucks better known as bobtails.

Bobtail truck definition

An LPG (propane) bobtail is a specialized bulk delivery vehicle custom built by manufacturers to hold from approximately 1000 to 5000 gallons of LPG. Built in a variety of sizes, a bobtail may contain different equipment and systems depending on when it was constructed and how it will be used. The bobtail is refilled at a bulk storage plant located at many different sites.

Besides bobtails there are also other types of LPG containers such as LPG Semi-Trailers and stationary storage tanks, both specialized containers for the storage of a larger capacity of LPG, but of which, we will talk about in an upcoming post.

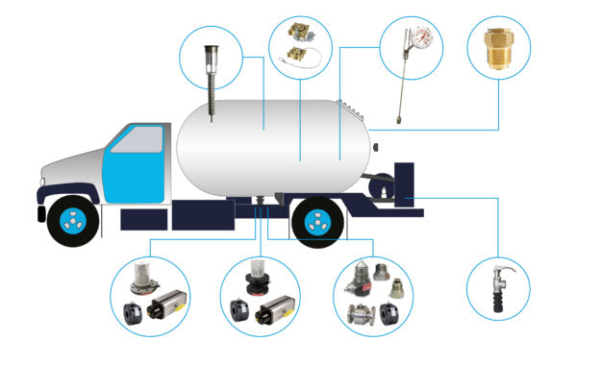

The set of components for Bobtail trucks includes: internal valves, pressure relief valves, float gauges, double check filler valves, hose-end valves, swivels, back checks, excess flow valves and ball valves.

In this post, we will cover the various internal valves available for bobtails.

Internal valves are available in 2 types of configuration depending on how they will be installed in the tank. Threaded internal valves have a large male thread that allows them to be installed into a female thread inside the tank and Flanged internal valves utilize a flange that requires specially designed bolts and nuts for installation. The flanged type is available in a single or double flange configuration.

Threaded internal valves are available in 1-1/4, 1-1/2, two and three inch sizes and flanged internal valves are available in 3 inch or 4 inch sizes.

How does an internal valve work?

The internal valve acts as the primary shutoff valve for the tank. The valve’s closing mechanism is located on the inside of the tank. This design allows the working components of the valve to remain functional in case damage occurs to any part of the valve located on the outside of the tank.

When the internal valve is in the closed position, the pressure of the LPG inside the tank pushes against the closing mechanism ensuring a leak tight seal is created inside the valve.

To open the valve, a lever arm is rotated about 70 degrees, which operates a cam inside the valve. This cam pushes against the valve stem allowing a partial opening, or bleeding, which lets some LPG flow through the valve. As LPG continues to partially flow through the valve, the downstream pressure will begin to increase. Once the downstream pressure equalizes with tank pressure, the internal valves main seat opens and full flow is achieved. The main seat also acts as an excess flow device and will shut closed in the event the flow of LPG exceeds the allowable flow rate.

When it is time to close the internal valve, the lever arm is rotated back to its original position, which closes the stem and the main seat instantly stopping the flow of LPG.

Internal valves can be outfitted with pneumatic actuators. These actuators allow the operator to remotely open and close the internal valve without the need to get below the tank.

Internal valves can also be installed with thermal latches. These latches will hold the level arm open during normal operation and will automatically release the lever arm, allowing the internal valve to close in the event that it is exposed to a fire or temperatures exceeding 212 degrees Fahrenheit. These latches can also be equipped with a cable that allows the operator to release the lever arm and close the valve from a remote distance.

There is more to read about other components available for each application, but to easier digest our content you will get it in portion-controlled sizes, so the next post will focus on pressure relief valves.