Propane Regulators have always played a key role within propane systems in terms of safety, as explained a few weeks ago in an article in LP Gas Magazine by Randy Warner, Product Safety Manager for Cavagna Group North America.

“The purpose of the regulator is to control the flow of gas vapor from the container to the burner tip of the appliance. As part of controlling the flow, the regulator also provides a level of safety by providing over pressure protection, typically through the means of a pressure relief device. This is why we often refer to the regulator as the heart of the propane system”.

In line with his commitment to spreading out the importance of safety in the gas world, Randy talked about the regulator as a key element in keeping a propane system operating effectively and safely. However, even a “safety device” as the regulator must be known in all its features and, Randy stated, it must never be modified, manipulated or repaired without being trained and have the approval of the manufacturer.

How do propane regulators work?

In order to guarantee an efficient operation of propane appliances and, thus, customer satisfaction and safety, it is very important to be knowledgeable on how a regulator works and, particularly on 2 critical phases: installation and operation.

Below, some basic guidelines that will help you to get a better understanding of the regulator, “heart” of the propane gas vapor system.

What makes a Propane Regulator

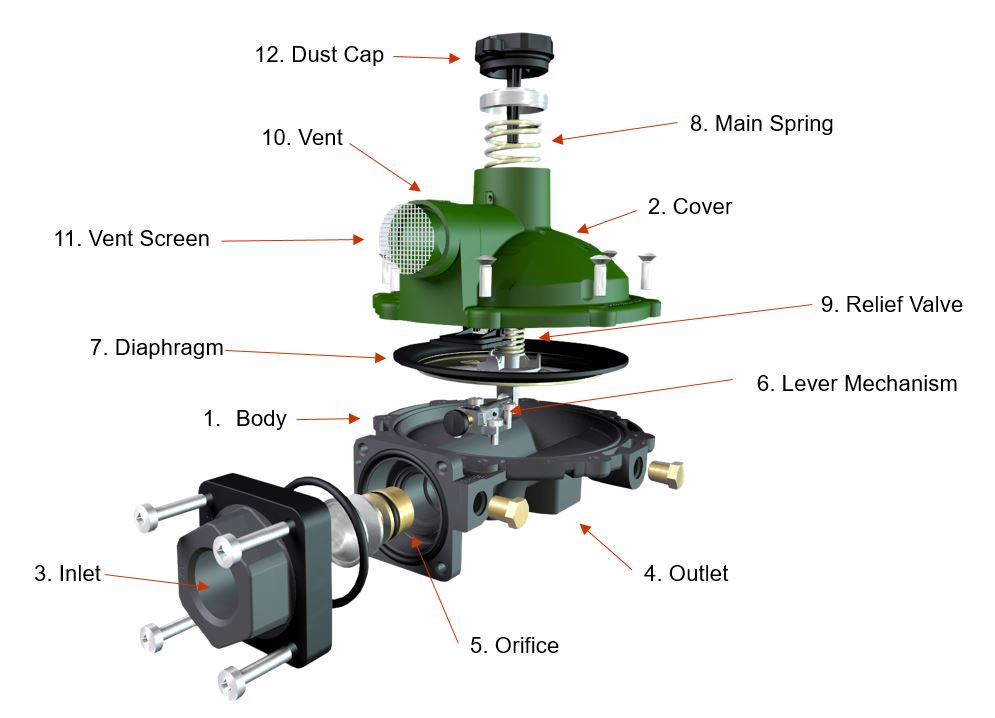

All regulators are made up of similar components and even though there are variations in features between manufactures, the basic components are the same in most propane regulators.

The basic parts that make up a regulator include:

- Body: the main physical portion of the regulator and typically is the lower portion.

- Cover: the upper part of the body and is typically color coded for its type of service. For example red could be for high pressure.

- Inlet port: where the source gas vapor enters the regulator

- Outlet port: where the source gas vapor exits the regulator.

- Orifice: determines the amount of vapor that can pass into the regulator.

- Lever: as the flow of vapor passes the orifice the lever pushes up on the diaphragm.

- Diaphragm: senses pressure and starts and stops the flow of gas vapor through the regulator.

- Main Spring: provides tension (force) on the diaphragm to regulate flow.

- Relief: if excess pressure flow beyond the capacity of the regulator occurs, the relief mechanism (spring) allows the propane vapor to exit through the relief. This prevents excess pressure to build through the outlet or downstream of the regulator.

- Vent: typically built into the cover and allows the regulator to breathe during normal operation; also it is typically where the relief mechanism discharges.

- Vent Screen: keep debris from entering the regulator.

- Dust Cap: allows you to visually see into the cover, retainer nut, and main spring.

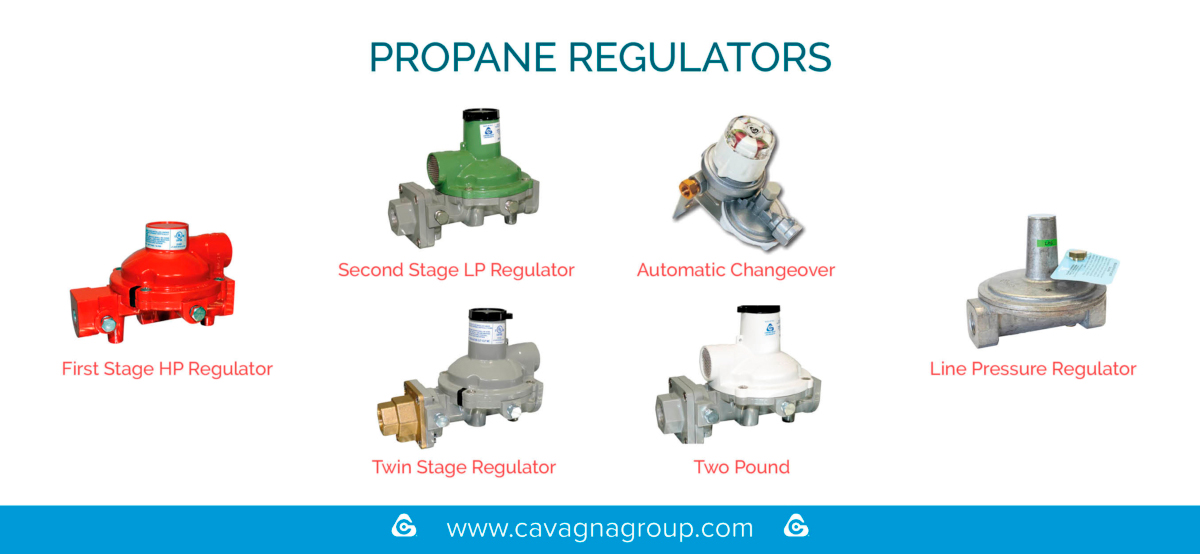

Types of Propane Regulators

Although the purpose of propane regulators is the same, there are many different types of regulators, designed to fit many different applications or functions.

Sizing a regulator correctly for the load on the system is also very important. The typical types of regulators used in residential applications include:

- First Stage (High Pressure) – Typically placed at the container and decreases the container pressure to 10 psi (0,70 bar).

- Second Stage (Low Pressure) – Typically placed at the residence and decreases the pressure from the first stage regulator to inches of water column (11 typically).

- Integral Two-Stage (Twin) – Some smaller load systems can accomplish taking the container pressure down to inches of water column by utilizing a regulator that has both stages built into a single regulator, sometimes referred to as a twin stage or piggyback regulator.

- Automatic Changeover – Similar to an Integral Two-Stage regulator in regard to pressure regulation, but also has a mechanism which allows it to monitor vapor pressure switching from one tank to another in a multi-tank installation where 2 or more cylinders are being used for the source.

- Two pound (2 lb.) –Typically placed at the residence and decreases the pressure from first stage regulator to two pounds. Used in newer systems where the gas vapor demand is needed, and requires additional regulation before the appliance.

- Line (appliance) –Typically placed before the appliance and decreases the pressure from two pounds to inches of water column (11 typically). There is no integral relief and typically uses a vent limiter.

Cavagna Group’s propane regulators

The Cavagna Group’s experience in terms of gas regulation lies in the 50 years history of RECA Unit.

Since 1970, RECA has been recognized, all over the world, as the most important brand in the gas regulation market.

RECA’s R&D Department is set in Italy but RECA also counts 5 worldwide production sites: working synergistically, they made it a leading producer of LPG, Natural Gas and High Pressure regulators. Today, its product range includes regulators for all different kind of applications.